Our Story

for 90 years

A reference point for the supply of steel products

Founded in 1934 in Mendrisio, Plastifil is still today a family-run company leader in Europe in the production of tailor-made products in steel wire.

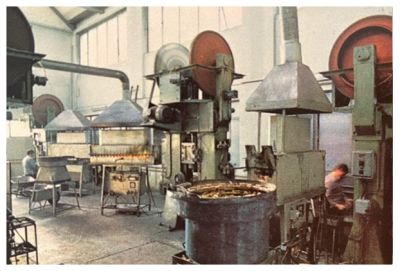

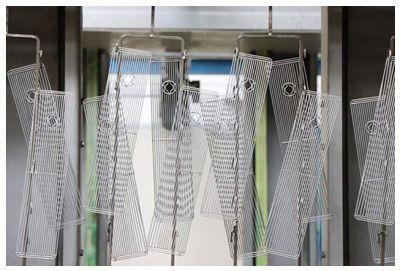

Initially known as Facta SA (Factory of Household Goods, Television and Allied Products) for the iron wire production of household goods and exhibitors, in 1954 it changed its name to Plastifil SA, when with the development of industrialization, it expanded its production to plastic-coated exhibitors and baskets for dishwashers.

Following the raising quality standards and the entry into increasingly technical sectors (such as medical, food and technical), Plastifil decides to replace iron wire with stainless steel wire.

The excellence of Made in Switzerland, the strong belief that complex problems need individual solutions, the constant technological adaptation in production and the constant monitoring of product quality, have allowed the company to stand out in the design and implementation of solutions globally.

for 90 years

A reference point for the supply of steel products

Plastifil SA is a Swiss family company founded in 1934.

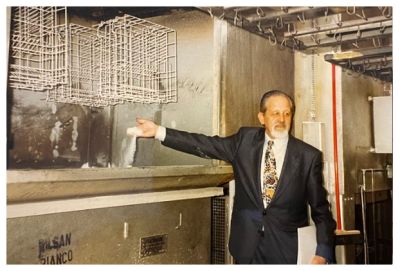

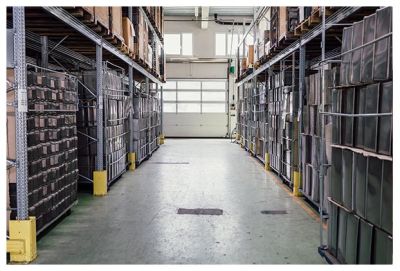

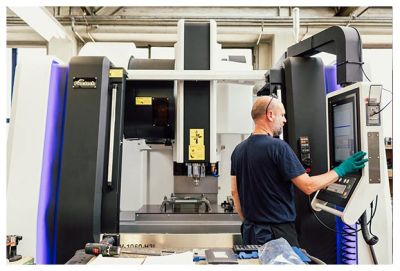

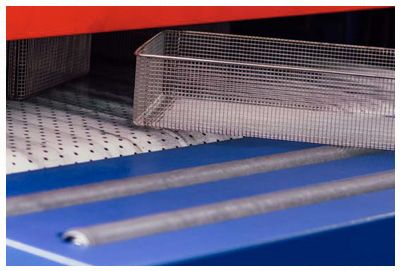

Located in Mendrisio, the company is now represented by the fourth generation of the same family of proprietors. It started out with seven emplovees under the name Facta SA, producing household items in wire, such as kitchen whisks and bird cages, before moving on to wire display racks for shops and newsstands. With the industrialization of the various processes and the advent of plastic coating for wires, the company was able to expand its production, supplying plastic-covered display stands and dishwasher racks, changing its name to Plastifil SA (plasti = plastification; Fil = steel wire). As quality standards increased and the company developed towards increasingly technical sectors, plastic-coated wire was replaced with stainless steel wire, designed and produced ad hoc for each client in the fields of industry, medicine, food preparation and design. In addition to being recognised as a company with verified equal pay, one of Plastifil’s goals is to keep its female and male employees at the centre of its business, promoting appreciation and fair development for them within the company. It ensures equal development opportunities in the various functions and roles. We firmly believe in Swiss-made quality, and in the key importance of offering a complete service to our clients, which is why, over the years, the company has invested in internalizing the various processes and services, starting from computer-aided design and manufacturing and the processing of raw materials right up to surface treatments (with heat-cured lacquering systems and plating baths). This has enabled Plastifil SA to specialize in every single stage of the production process, even offering its clients total control over the final quality of the product and the intermediate processes, together with great flexibility in the management of the materials and supplies using the kanban system.Thanks to its great attention to detail and quality, the company has earned the trust of leading international companies in their respective fields, as well as the major Swiss watchmaking brands.

Timeline

The company is founded under the name Facta SA in Capolago, in the Canton of Ticino, sole director Dr Dante Ronchetti.

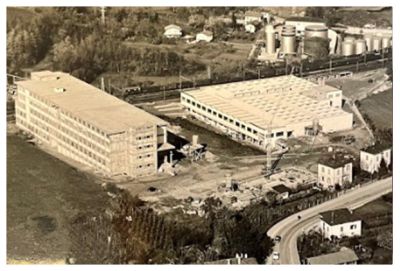

The company opens a new factory in Mendrisio which it then moves to.

The company changes its name to Plastifil SA (plasti = plasticisation; fil = steel wire) with the advent of innovative plastics, which are a breakthrough in several areas and sectors for metal wire coating.

Expansion with a new factory in industrial zone 7 in Mendrisio. A strategic area with major access roads, highways and motorways.

The construction of a siding with the FFS national network thus enhances freight transfer.

The Director Mario Snozzi (2nd generation) is appointed Chairman. His two sons-in-law, Emilio Pastori and Claudio Piccioli Cappelli (representing the 3rd generation) join him on the Board of Directors.

The wing for the new automatic epoxy powder coating plant is opened.

A new wing of the factory is built, used for storage and expansion of the processing departments for the machines, automatic folding machines.

Michele Matis succeeds as the new Chief Executive Officer. The company obtains FDA certification in the medical field and passes to the new ISO 9001:2015 certification.

Major investments undertaken with new CNC centres for quality in turning and milling. Additional islands added for robotizing processes, which require continuous training for company staff.

With a focus on the present and a futuristic outlook, a new automated electro-cleaning and passivation line for process optimisation is installed.

Installed the new treatment tunnel with 3 stages for washing and degreasing in the thermo-lacquering department.

Plastifil invests in the installation of photovoltaic panels on the entire roof of the company, in Line with its focus on the territory and the importance of caring about resources.

Honorary President Mario Snozzi leaves us. His foresight, dedication to work, friendliness and elegant ways will remain as values to guide us for the future of Plastifil SA.

A new machine for automated wire straightening and deburring is installed.

New equipment for making stainless steel wire rings.

Plastifil invests in quality, with a new highly automated laser measuring instrument, in process improvement and in new robotic and manual laser welding and wire bending equipment.

We are co-creators

of innovative solutions

PRODUCTS

© Plastifil SA. All rights reserved.

Powered by SHOCK THE RULES.